Soft tennis was an alteration of tennis, from the late 19th century conception in Japan. In comparison to ordinary tennis, this version has different ball material, softer as compared to the other materials utilized by standard tennis, thus giving different playing sensations. Soft tennis balls have always had superiority between durability, playability, and performance. This is followed by the evolution history of the soft tennis ball and how different technologies influence them to reach optimal output. Techniques are reviewed to show production procedures:

Evolution of Soft Tennis Balls

1. Origin of Soft Tennis

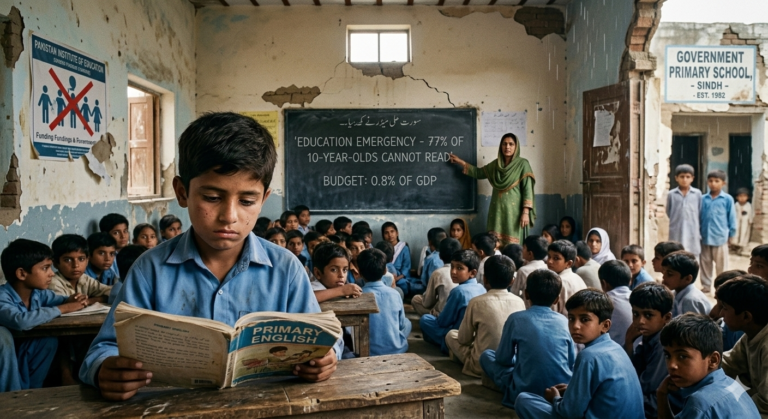

Soft tennis is the original version and first put into practice in Japan in 1884. In fact, the idea introduced lawn tennis; with that, it did include much softer balls for better maneuverability. According to many, the purpose was in coming up with an original idea of a game wherein everybody could play- but was easy to manage for age and capabilities differences. This adaptation emphasized a softer, lighter ball and easy to handle, requiring less effort than an ordinary tennis ball.

2. Early Designs and Materials

Since it was elastic and soft, early soft tennis balls were made from natural rubber. Comparing with the pressurized felt-covered balls that are used for regular tennis, early soft tennis balls were hollow, single-layer thin rubber. The objective of these designs was that they should bounce softly and would be slower for leisure games.

3. Technological Advancements

Advancement of material science and manufacturing have made the soft tennis balls very much softer and qualitative and performance better. Innovation points as follows:

Stronger: The new balls are made with advanced rubber compounds that are resistant to abrasion, thereby maintaining shape and performance for a longer time.

Precision Engineering: New manufacturing processes ensure consistent size and weight and bounce, like international standards for competitive use.

Eco-Friendly Materials: Environmental awareness has also increased with higher usage of more environmental-friendly materials and technologies in the production of soft tennis balls to have a minimum damage on the ecological system.

4. Modern Standards

Today, soft tennis balls are manufactured under the regulations of the ISTF. All the balls are of the same size in diameter, which falls between 6.6 and 6.9 cm; uniform weight: between 30 and 31 grams; and have uniform bounce so that thus fair play at all stages of the game prevails.

How Soft Tennis Balls Are Made: Secrets Revealed

The finest soft tennis balls in the world do not come cheap-it requires material expertise, precision manufacturing, and tough quality control. Let’s roll and find out some of the important steps and secrets in this production process below.

1. Material Selection

The main material used for the preparation of soft tennis balls is vulcanized rubber. This material is used due to its elasticity, strength, and resistance to impacts. Specific compounds can be added for better resistance to cracking and deformation in case of manufacture for better performance and long life.

2. Rubber Molding

The first stage of the manufacturing process would be the molding of rubber into hemispherical halves. The halves are produced in molds with specific designs, precision, and a smooth finish. These factors are essential considerations in ensuring uniform size and weight.

3. Halves Assembly

By using precision vulcanization techniques, these pieces of rubber bond by combining the two halves.

In this vulcanizing process, there is a very tight seamless bonding of the rubber after heating. This ensures that the ball will leak no air and, in this respect, should have its structure in own once during play.

4. Surface Texturing

The surface of the ball has textures or embossing to provide a good grip and control. It would be very important for the serious tennis player since it provides the means of higher spin and accuracy during a game.

5. Quality Control

Soft tennis balls are put through rigorous tests with strict quality control procedures before their products pass international standards. They are tested based on the following:

Bounce Test: The bounce of the ball is checked within the acceptable limit.

Durability Test: The ability of the ball to face multiple knocks without changing its shape

Weight and Size Check: All the produced units are identical

6. Packing and Delivery

After the passing through the quality assurance, it is packaged, and those send to retailers, clubs, and many players in the world occur.

In most instances, it covers the care of the soft tennis balls on how to store them within its lifetime.

Soft Tennis Ball Innovation and Manufacturing

1. Customization for Performance

Soft tennis balls for the particular condition or one’s own choice in playing.

For instance, balls that are hard or bouncy are readily available for particular skill levels and court surfaces.

2. Eco-Friendly Practices

Manufacturers have resorted to producing in ways that have become eco-friendlier. This includes the use of biodegradable materials, and the reduction of wastes. The steps help in achieving sustainability in the world and attract the environmentally concerned players to the sport.

3. Smart Balls

New emerging technologies pave the way to “smart” soft tennis balls, soft with sensors inside, tracking performance metrics like speed, spin, and trajectory. This will revolutionize training and analysis in this sport.

FAQs

1. What makes soft tennis balls different from regular tennis balls?

These balls are made of rubber, soft, less pressurized and less heavy than the normal ones and do not use felt as the most have. It is better for controlled and slower games.

2. How are soft tennis balls preserved?

To prolong the lifetime of soft tennis balls, store them in a cool dry place away from direct sunlight. Store it at extreme temperatures and also avoid putting sharp objects where piercing the rubber might damage.

3. Are soft tennis balls environmental friendly?

There are countless types of soft tennis balls made from eco-friendly material and processes. Many manufacturers produce soft tennis balls from biodegradable rubber. They also produce keeping low carbon emissions.

4. How long will soft tennis balls last?

Again, depending on usage and handling, the soft tennis ball can last anywhere between a few months for someone playing recreationally to only a few weeks for top professional players that are competitive at the highest level.

5. Are soft tennis balls applied for other games?

Although they are designed for soft tennis, they can still be applied in practice or some small games or as toys for children, since they are soft and light.

6. What are the official regulations covering soft tennis balls?

ISTF regulates its diameter to lie between 6.6 and 6.9 cm. Its weight ranges between 30 and 31 grams. Bounce and hardness must also be met.

7. In what way does technology influence the soft tennis ball?

Technology has made the product more accurate and reliable, made possible the integration of environmental-friendly materials, and enabled a few inventions such as the smart ball with sensors to track its performance.